In the fast-paced world of logistics and product distribution, packaging plays a crucial role in maintaining product quality, improving safety, and enhancing brand presentation. Shrink wrap packaging has gained popularity across multiple industries as a reliable and efficient method for securing and protecting goods. But how do you know when it’s time to switch from traditional packaging to shrink wrap?

Whether you’re managing a growing business or reevaluating your production line, transitioning to shrink wrap packaging could be the upgrade your operations need.

What Is Shrink Wrap Packaging?

Shrink wrap involves covering a product or a group of items with a plastic film that shrinks tightly when heat is applied. The result is a clean, tamper-evident seal that conforms to the shape of the packaged item. It’s widely used for everything from food and beverages to electronics and industrial supplies.

This method not only protects against dirt, moisture, and tampering but also provides a professional finish that’s ideal for retail display.

Signs It’s Time to Make the Switch

1. Increased Product Volume

If your business is experiencing growth and your production volumes are climbing, traditional packaging methods may become too slow or labor-intensive. A shrink film wrapping machine can automate the packaging process, significantly improving speed and consistency.

This not only reduces labor costs but also minimizes human error, leading to a more streamlined workflow.

2. High Packaging Waste or Costs

Packaging materials like boxes, tape, and fillers can become expensive over time, especially when shipping large quantities. Shrink wrap uses minimal material, reducing overall waste and cutting down on both supply costs and shipping weight.

By switching to shrink wrap packaging, businesses can save money and support sustainable practices with reduced packaging waste.

3. Need for Improved Product Protection

Products in transit or on display need protection from dust, dirt, and moisture. Shrink wrap creates a tight, sealed barrier around your items, keeping them clean and tamper-resistant.

If you’ve faced issues with product damage during shipping or storage, shrink wrap is a practical solution. It also offers UV protection and can extend shelf life, especially for perishable goods.

4. Demand for Better Presentation

Presentation matters, especially for retail products. Shrink wrap gives products a sleek and professional look that allows clear visibility while keeping contents intact. Whether you’re wrapping multi-item bundles or single units, shrink wrap enhances shelf appeal without sacrificing durability.

When consumers can clearly see what they’re buying, while trusting it’s safe and secure, it builds brand confidence.

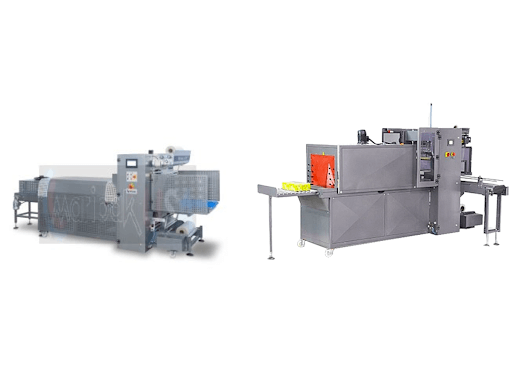

Benefits of Using a Shrink Film Wrapping Machine

Investing in a shrink film wrapping machine can be a game-changer for medium to large-scale businesses. These machines automate the sealing and shrinking process, allowing for high-volume packaging with consistent quality.

Some key benefits include:

- Speed: Packages more products per hour compared to manual wrapping.

- Consistency: Ensures uniform seals and shrinkage for every item.

- Versatility: Works with various shapes and sizes of products.

- Labor Efficiency: Reduces the need for manual intervention, allowing staff to focus on other tasks.

The upfront investment often pays for itself in a short time, especially for businesses dealing with bulk orders.

Is Shrink Wrap Right for Your Business?

Before making the switch, evaluate your packaging goals. Do you need to reduce waste, cut costs, speed up production, or improve shelf presentation? Shrink wrap offers all of these benefits and more, making it a strong contender in any packaging strategy.

Additionally, many shrink wrapping machines are scalable, allowing you to start small and expand as your needs grow.

Final Thoughts

Switching to shrink wrap packaging can significantly improve operational efficiency, reduce costs, and enhance product protection and presentation. If you’re managing increasing order volumes or aiming for a more professional and sustainable packaging solution, now might be the right time to invest in a shrink film wrapping machine.

Make the transition thoughtfully by choosing the right equipment and ensuring your team is ready to integrate it into your workflow. The results? A faster, cleaner, and more cost-effective packaging process that scales with your business.