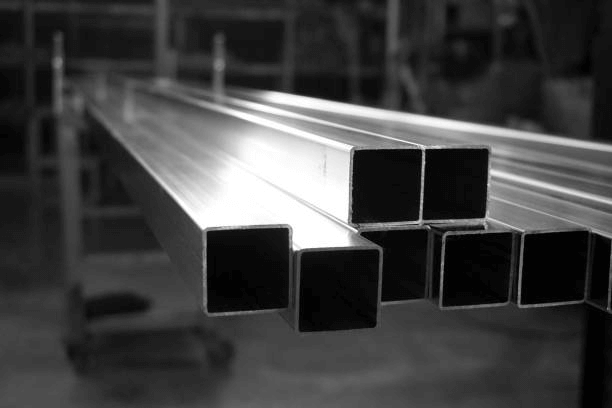

Square tubing has emerge as a staple in contemporary creation and fabrication due to its energy, geometric uniformity, and flexibility. It’s utilized in applications ranging from industrial buildings to fixtures frames and agricultural device. The hollow design and four-sided power of square tubing make it perfect for sporting structural loads while retaining fabric efficiency. As part of the wider own family of structural steel products, it gives designers and engineers a reliable and value-effective solution across various sectors.

However, like every structural components, rectangular tubing isn’t always proof against the outcomes of time, climate, wear, and environmental stressors. Preserving its integrity is important for safety, overall performance, and lengthy-term fee. Extending the lifestyles of square tubing systems entails a combination of thoughtful design, nice fabric choice, proper installation, and ongoing protection.

Material Selection and Initial Design Considerations

Choosing the Right Grade and Thickness

The first factor in ensuring toughness is choosing the proper grade and wall thickness of square tubing. Different grades offer various stages of tensile power, corrosion resistance, and weldability. In outdoor or high-stress environments, thicker walls or higher-electricity metal grades can dramatically improve resistance to deformation and fatigue. Lightweight systems, then again, might prioritize tubing with thinner walls for cost and ease of installation, however that incorporates exchange-offs in sturdiness.

The chosen material must be aligned with the predicted load, exposure situations, and intended lifespan. Design alternatives made early within the making plans phase have a long-lasting effect at the shape’s ability to resist deterioration.

Incorporating Smart Structural Design

Effective design additionally plays a position in how rectangular tubing performs through the years. Avoiding needless stress factors, decreasing load concentrations, and ensuring balanced distribution of forces can mitigate the threat of premature failure. Weld placement, joint reinforcement, and the usage of gussets wherein wished are easy but powerful approaches to enhance universal structural overall performance.

Drainage have to be factored into designs that involve rectangular tubing in outdoor or moisture-inclined environments. Because tubing is hole, trapped water can result in inner rusting if right drain holes or sealed ends are not protected inside the initial layout.

Protective Coatings and Corrosion Resistance

Galvanization and Zinc-Based Coatings

One of the best approaches to increase the life of square tubing is through protecting coatings. Galvanization, which includes making use of a zinc coating to steel surfaces, presents a protracted-lasting defend against corrosion. The zinc acts as a sacrificial layer, corroding in location of the underlying metal. This technique is mainly useful for outdoor packages or in regions with excessive humidity and saline publicity.

Hot-dip galvanization offers strong, all-round protection, consisting of interior surfaces, that’s crucial for hole tubing. Other zinc-primarily based coatings, which includes electroplating, can also be implemented depending at the surroundings and performance necessities.

Powder Coating and Paint Finishes

For indoor or much less aggressive environments, powder coating provides each aesthetic appeal and purposeful protection. This manner applies a dry, electrostatically charged powder this is cured under warmth, forming a tough finish that resists chipping, scratching, and corrosion. Powder coatings are available numerous colorations and textures and are regularly utilized in architectural or customer-facing programs.

Paint finishes, even as greater liable to put on, still provide a fee-powerful solution for temporary safety or systems which can be regularly inspected and maintained. Repainting may be part of a everyday maintenance schedule to make certain lasting overall performance.

Proper Installation Techniques

Avoiding Galvanic Corrosion

When rectangular tubing is used in combination with distinct metals, care need to be taken to prevent galvanic corrosion. This occurs while distinctive metals come into electrical contact within the presence of an electrolyte, which include moisture. The more reactive metallic corrodes quicker, doubtlessly weakening joints and connections. Using suitable insulators or matching materials helps minimize this danger throughout installation.

Joint sealing, correct fasteners, and well suited welding materials are also essential to avoid degradation over the years. Installation groups have to comply with high-quality practices and cling to engineering specifications that account for both mechanical overall performance and chemical compatibility.

Ensuring Stable Foundations and Anchoring

No rely how nicely the tubing is made or coated, its durability can be compromised by means of fallacious set up. Ensuring that rectangular tubing structures are securely anchored to stable foundations is critical. Uneven settling, shifting soil, or terrible concrete work can introduce stresses that the tubing was now not designed to deal with.

Precision alignment at some stage in meeting also enables save you needless anxiety or torsion inside the framework. Misaligned additives may flex or twist under load, which quickens fatigue and potential failure. Following strict tolerances and the use of calibrated tools during creation is essential.

Regular Maintenance and Inspection Protocols

Establishing a Maintenance Schedule

Even the most long lasting systems require ongoing care. Establishing a renovation schedule permits early detection of wear and tear, corrosion, or physical damage. Inspections must test for paint or coating screw ups, symptoms of rust, deformation, and stress cracking. When issues are diagnosed early, they may be typically less difficult and greater cost-effective to repair.

Surface cleansing is any other critical part of renovation. Accumulated dust, moisture, or commercial contaminants can put on down shielding coatings or promote corrosion. Washing and drying surfaces periodically helps preserve the coating integrity and the underlying metal.

Performing Timely Repairs

Small problems, if left unaddressed, can quickly evolve into fundamental structural issues. For example, minor rust spots can expand under coatings, weakening the tubing’s wall and compromising structural stability. Cracked welds, loose fasteners, or dented sections need to be repaired promptly using accredited substances and strategies.

When maintenance contain replacing broken sections of tubing, the new cloth have to in shape the original in grade and dimensions to make certain constant performance. Repairs must additionally repair protecting finishes to keep corrosion resistance and visible uniformity.

Environmental Considerations for Longevity

Exposure to Weather and Chemicals

Structures which are placed in harsh climates or commercial environments face extra stressors. High stages of humidity, salt, or chemical fumes can attack shielding coatings and boost up steel deterioration. In these settings, more advantageous corrosion-resistant materials, thicker coatings, or chrome steel variations of rectangular tubing may be vital.

Designers and renovation groups must assess environmental risks and plan for that reason. For example, coastal regions may additionally require marine-grade coatings or multiplied inspection frequency. Shielding or enclosing the tubing can also mitigate direct publicity to harsh situations.

Mitigating Impact and Vibration

Vibrations and repeated mechanical influences can loosen joints, put on out coatings, and fatigue the tubing through the years. Equipment mounts, support structures, and cellular frameworks must be checked for vibration dampening, proper alignment, and factor stability. Use of rubber isolators, bendy joints, or electricity-absorbing supports can greatly enlarge service life in dynamic settings.

Monitoring vibration and impact over the years via sensors or scheduled exams can manual renovation schedules and save you surprising breakdowns.

Lifecycle Planning and Structural Redesign

Retrofitting for Extended Use

In cases where rectangular tubing systems have aged but nonetheless serve a reason, retrofitting will become a possible approach. This may contain reinforcing joints, changing deteriorated sections, or adding new coatings. Retrofitting lets in older systems to fulfill modern requirements without the price and waste related to entire replacements.

Evaluating load-bearing capacities, figuring out susceptible points, and upgrading materials or layout additives are all a part of a a hit retrofit method. Proper evaluation with the aid of engineers guarantees that such modifications make bigger lifestyles with out compromising protection.

Planning for Disassembly and Reuse

One benefit of rectangular tubing systems is that they can regularly be disassembled and reused. This now not best extends their provider life but additionally supports sustainability and cost savings. Planning for eventual reuse all through the layout stage—through modular construction, bolt-collectively joints, and smooth-to-eliminate coatings—enhances the circular lifecycle of structural steel additives.

Disassembled tubing must be inspected, wiped clean, and recoated as important earlier than being repurposed. When well maintained, reused square tubing can offer the identical overall performance as new materials in secondary applications.

Conclusion: Durable Design Through Preventive Action

The lengthy-term performance of rectangular tubing systems depends on a complete method that starts with smart layout and extends via careful installation and diligent upkeep. As a key member of structural steel products, square tubing gives each form and feature, however it ought to be handled with foresight and responsibility to attain its full capacity.

Whether used in homes, bridges, machinery, or decorative frameworks, square tubing can final for many years with the right strategies in vicinity. By addressing environmental publicity, making use of protective finishes, and scheduling habitual inspections, engineers and builders can make certain that these flexible metal components continue to serve thoroughly, efficaciously, and sustainably through the years.